What is a Bottle Cap Torque Tester?

A Bottle Cap Torque Tester is a specialized device that measures the torque force required to open or close a bottle cap. The right amount of torque is essential to ensure that caps are neither too tight (which can make them difficult to open) nor too loose (which can cause leaks and contamination). This tester helps manufacturers verify that each bottle cap has been applied correctly, providing a reliable seal for a variety of bottle types and closure systems.

Whether you’re dealing with plastic, glass, or metal containers, the Bottle Cap Torque Tester ensures that the caps are securely fastened to maintain the safety and quality of your products.

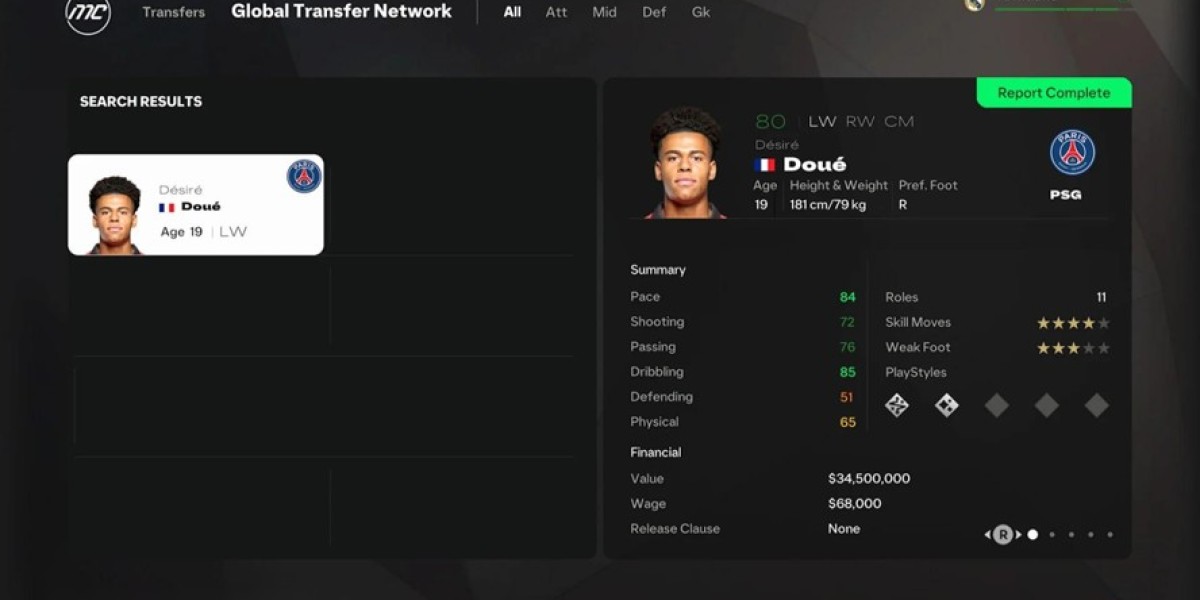

Key Features of the Bottle Cap Torque Tester

1. Accurate Torque Measurements:

Pacorr’s Bottle Cap Torque Tester offers precise and reliable torque readings, ensuring consistent cap sealing across all production batches. This accuracy is essential for maintaining product integrity and avoiding costly packaging defects.

2. Wide Range of Compatibility:

This tester is designed to work with a variety of bottle types, including plastic, glass, and metal, making it versatile for industries ranging from food and beverages to pharmaceuticals and cosmetics.

3. Easy-to-Use Digital Display:

The digital interface of the Bottle Cap Torque Tester provides real-time torque values, making it simple for operators to interpret results and make necessary adjustments quickly.

4. Meets International Standards:

Our Bottle Cap Torque Testers comply with globally recognized standards such as ISO 17712 and ASTM D3332, ensuring your packaging process meets industry regulations and provides consistent product quality.

5. Data Logging and Analysis:

Advanced models come equipped with data logging capabilities, allowing manufacturers to store, review, and analyze torque testing results over time. This feature is essential for maintaining long-term quality control and ensuring product consistency.

Benefits of Using a Bottle Cap Torque Tester

1. Ensures Product Safety:

By applying the right amount of torque, the Bottle Cap Torque Tester ensures that bottles are securely sealed, preventing leaks, contamination, and spoilage. This is particularly important for products like food, beverages, and pharmaceuticals, where packaging integrity is vital.

2. Increases Operational Efficiency:

With real-time torque testing, manufacturers can quickly adjust their sealing process to ensure that each bottle cap is applied correctly. This improves overall production speed and reduces downtime due to faulty seals.

3. Enhances Customer Satisfaction:

Consumers expect bottles to be easy to open but securely sealed. The Bottle Cap Torque Tester helps manufacturers meet this expectation by ensuring that every bottle cap is correctly tightened, improving the overall user experience.

4. Reduces Costs from Packaging Defects:

By identifying torque-related issues early in the production process, the tester helps prevent defects such as loose or over-tightened caps, reducing the risk of product recalls and costly waste.

Applications of the Bottle Cap Torque Tester

The Bottle Cap Torque Tester is essential in industries where product sealing plays a key role in maintaining quality. Some common applications include:

Food and Beverage Industry: Tests the torque on caps of beverages, sauces, and other liquid products to ensure they are sealed tightly for freshness and safety.

Pharmaceutical Industry: Verifies that pharmaceutical products are securely sealed, providing tamper-proof packaging for medicines and health products.

Cosmetics and Personal Care: Ensures that bottles of lotions, shampoos, and other personal care products are tightly sealed to prevent leakage and contamination.

Chemical Packaging: Assesses the torque of caps on chemical products, ensuring that containers are properly sealed for safe transportation and storage.

Why Choose Pacorr’s Bottle Cap Torque Tester?

Pacorr Testing Instruments Pvt Ltd is known for its commitment to quality and precision. Our Bottle Cap Torque Testers are built with advanced technology to ensure that your packaging process is consistent, efficient, and compliant with industry standards. By choosing Pacorr, you are investing in a tool that helps improve production efficiency, product quality, and consumer safety.

With our Bottle Cap Torque Tester Price, manufacturers can ensure that their products are reliably sealed, minimizing the risk of packaging-related issues while enhancing customer satisfaction.

Conclusion

The Bottle Cap Torque Tester is a must-have tool for manufacturers who care about the integrity and safety of their products. Whether you are in the food, pharmaceutical, or cosmetics industry, ensuring that your bottle caps are properly sealed is essential to maintaining product quality and preventing leaks. By investing in Pacorr Testing Instruments Pvt Ltd, you ensure a secure packaging process that meets the highest industry standards.

For more information on how our Bottle Cap Torque Tester can benefit your packaging process, visit pacorr.com.