Banana Roller Manufacturers and Their Role in Web Handling Efficiency

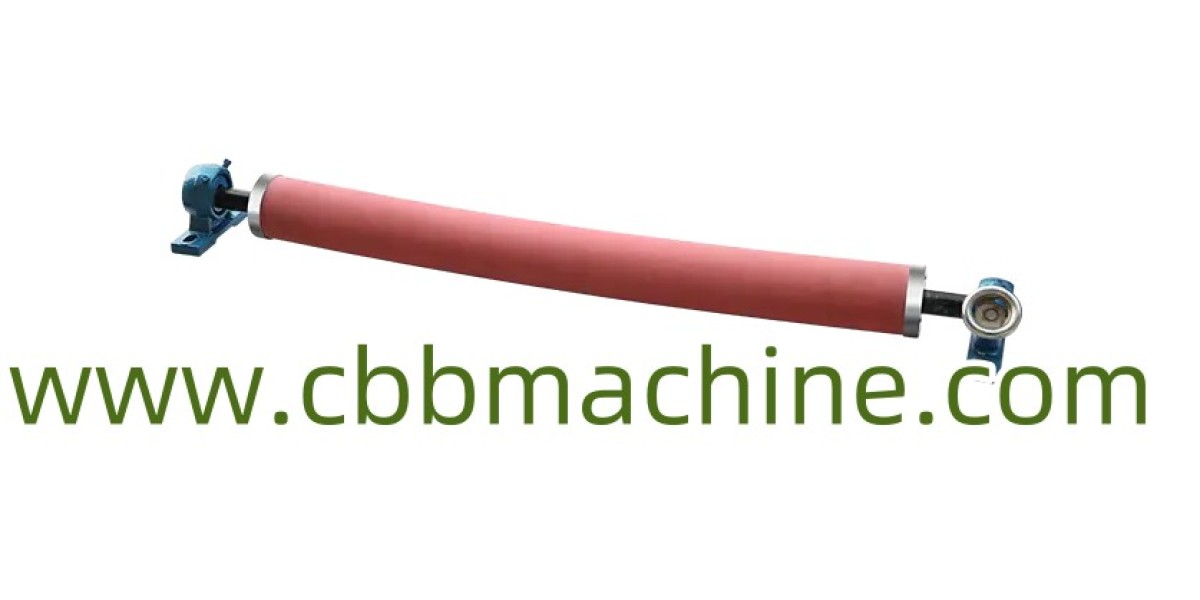

Banana Roller manufacturers play a key role in the advancement of web handling systems across industries such as printing, packaging, plastic film, textiles, and converting. These specialized rollers—named for their gentle curve resembling a banana—serve a very specific function: eliminating wrinkles and maintaining even tension across materials being processed on high-speed machinery.

In modern production lines, maintaining consistent tension and avoiding defects like creases, slack edges, or air pockets are essential for product quality. This is where the curved design of the banana roller becomes beneficial. Unlike traditional rollers, banana rollers are engineered to gently spread the web laterally, smoothing out any uneven areas and preventing wrinkle formation. The effectiveness of this process depends largely on the precision and reliability offered by experienced Banana Roller manufacturers.

What sets banana rollers apart is their unique ability to apply differential pressure across the width of the web. When the material passes over the curved surface, it experiences a slight stretch on the sides, which evens out the surface tension. This ensures that the material remains flat and properly aligned throughout the process, minimizing the chance of costly defects. This principle makes banana rollers indispensable in applications involving thin films, stretchable materials, or sensitive substrates that can easily deform under inconsistent force.

Choosing the right banana roller involves considering several technical factors, including the material of the roller, the curvature radius, rotation speed, and the type of bearings used. Most banana rollers are constructed from lightweight yet durable materials like aluminum or stainless steel, sometimes coated with rubber to enhance grip and reduce static. Manufacturers often offer customization options for shaft dimensions, surface coatings, and balancing to suit specific applications.

Reliable Banana Roller manufacturers ensure that the rollers they supply are dynamically balanced to prevent vibrations, which could disrupt high-speed operations. They also provide rollers with adjustable curvature mechanisms, allowing users to fine-tune the spread depending on material behavior and line speed. This kind of flexibility is especially important in processes where different materials are used interchangeably or when multiple web paths are present.

Another essential factor in the banana roller’s success is its low-maintenance design. Many of these rollers are built with sealed bearings and corrosion-resistant finishes, which enhance their longevity and reduce the frequency of replacement. This contributes to operational efficiency and lower overall production costs.

Beyond their mechanical design, the support from experienced Banana Roller manufacturers is critical. Manufacturers with a deep understanding of web dynamics and machinery integration can offer valuable technical guidance, helping users select and install rollers that align perfectly with their equipment and operational goals. They also offer post-sale services like installation assistance, calibration support, and long-term maintenance advice.

As automation continues to shape industrial production, banana rollers are increasingly being integrated into smart systems. Sensors can be added to monitor tension, track roller wear, and adjust spread angles in real time. This modern approach not only improves consistency but also helps reduce downtime caused by manual adjustments or material waste due to errors.

Banana rollers are also crucial in high-precision applications such as optical film coating and medical-grade packaging. In these fields, even microscopic wrinkles or tension fluctuations can render a product unusable. Manufacturers who deliver rollers with high concentricity and custom geometry help ensure that such standards are reliably met.

In conclusion, banana rollers are more than just a curved component on a web line—they’re a critical element for maintaining quality and reducing waste. Partnering with capable Banana Roller manufacturers ensures access to expertly crafted, reliable components tailored to exact needs, contributing to smooth, efficient production workflows.